STEINEMANN (SHANGHAI) MACHINERY CO., LTD.

Booth Number: Hall 7.1 - 7.1B30

Add WMF Wechat for consultation

Share this page

Exhibitor E-invitation

Exhibit E-card

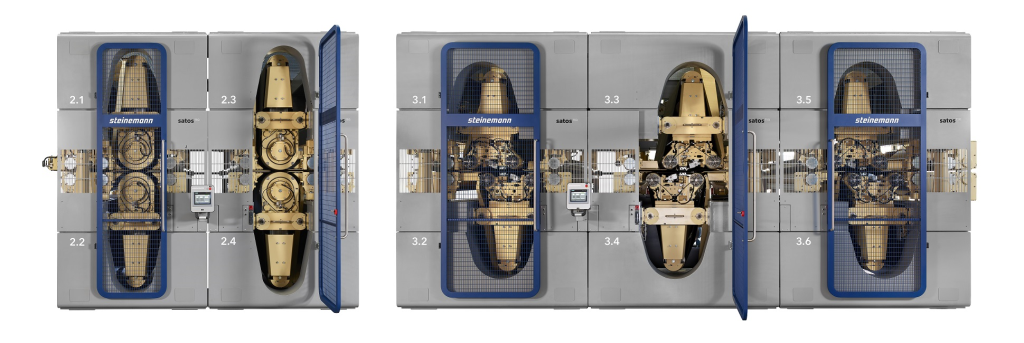

SATOS TSQ

Exhibit Highlight: SustainabilityHigh-end Home Customization ToolsSmart Production

The latest generation of machines in the satos product range, the satos TSQ, offers the customary Steinemann quality with cutting-edge software and hardware technology. The TSQ is well equipped for the future and includes BQC-readiness and all the necessary software components as standard so that the machine can be fully integrated into the complete production process in wood-based panel production.

The focus goes far beyond the mere sanding of the panel surface with the satos TSQ. In the development of the new generation of machines, the sanding machine is not viewed as an independent part of the sanding line, but as the interacting centerpiece. Steinemann is therefore taking the first major steps towards a fully automated sanding process.

With advanced sanding belt logistics, we are providing a basis for optimum logistics and space utilization on the sanding line.

BQC - BOARD QUALITY COCKPIT

Exhibit Highlight: SustainabilityHigh-end Home Customization ToolsSmart Production

The BQC process control system offers a modular approach to performance. Three coordinated retrofit packages let you achieve tailor-made automation for your individual sanding processes, plus the full integration of Satos into your overall production line.

The combination of the Satos family and BQC represents a giant step towards our ultimate goal: the fully automated sanding process. In this scenario, BQC operates separately from the machine software as an autonomous software suite that networks with all of the sanding line peripherals. We offer a number of automation packages that enable the complete integration and

automation of the sanding process. Depending on the choice and combination of the various BQC packages and modules, the sanding process can be almost entirely automated.

思源黑体预加载(勿删): STEINEMANN (SHANGHAI) MACHINERY CO., LTD.