JIANGSU LEEV INTELLIGENT EQUIPMENT CO., LTD.

Booth Number: Hall 8.1 - 8.1H45

Add WMF Wechat for consultation

Share this page

Exhibitor E-invitation

Exhibit E-card

CARTON CUTTING MACHINE

Exhibit Highlight: High-end Home Customization ToolsSmart ProductionSmall Batch Production

Used for continuous fixed length processing of corrugated paper and making folding cardboard boxes; Machines perform horizontal and vertical line pressing, intermittent cutting, and cutting processing on corrugated paper; Can be produced in large quantities; The cutting control system uses one servo to control one knife, and adjusts the knife in one step; Optimized the anti paper jam mechanism and designed a triple anti paper jam mechanism to solve the problem of paper jam; The storage adjustment mechanism adopts precision gear chain transmission for lifting and lowering, ensuring the level and synchronization of the paper feeding port.

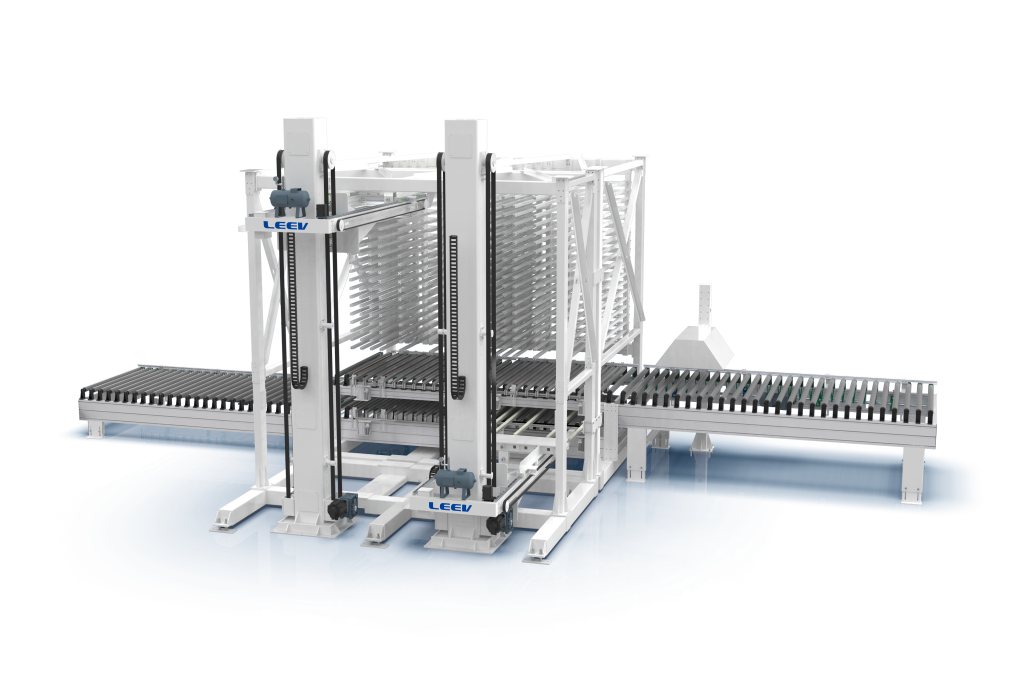

INTELLIGENT SORTING STORGE

China debut

Exhibit Highlight: High-end Home Customization ToolsSmart ProductionSmall Batch Production

Suitable for sorting tasks in order consolidation production or individual mode for each order; Docking and dismantling software or pre subcontracted software data, sorting them into cabinets or packages; It can also be used for sorting orders after packaging and before shipment; Large capacity 20 floors with 160 storage spaces (1300 * 300 * (8-25) mm); Depending on the product and efficiency, an average of 4-15 tablets can be produced per minute; Including pre subcontracted software; Small footprint.

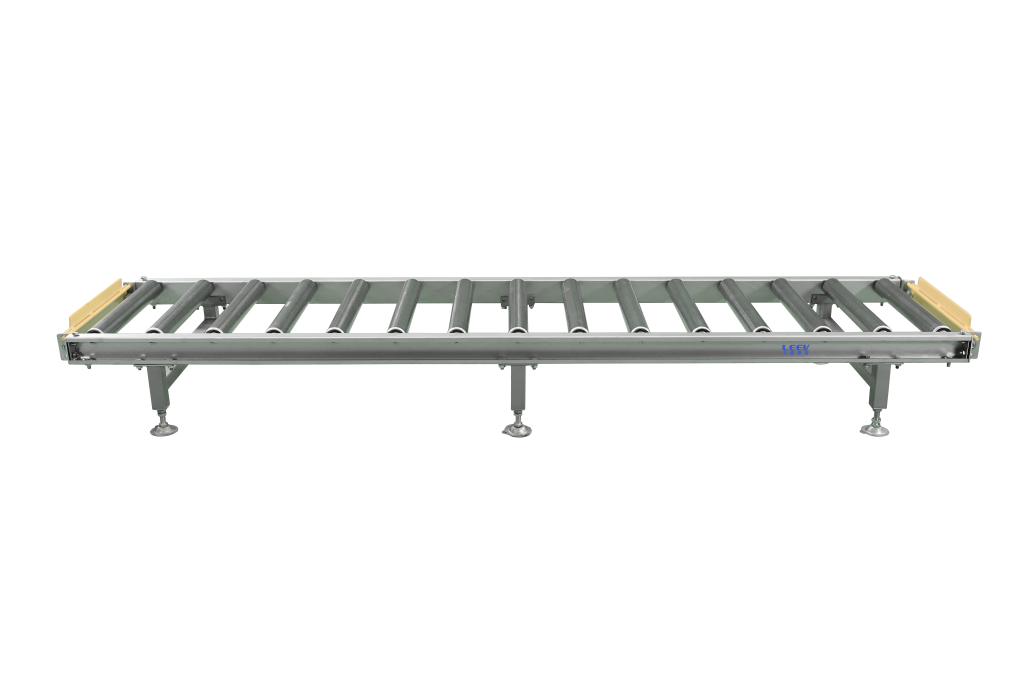

ROLLER CONVEYING LINE

Exhibit Highlight: SustainabilityHigh-end Home Customization ToolsSmall Batch Production

The main beam is made of hot-dip galvanized sheet and treated with hot-dip galvanizing on the drum, which is wear-resistant and corrosion-resistant, and has a long service life. It is suitable for conveying and circulating stacked panels to various processes in furniture production workshops. It can be used as a buffer zone between two processes to store panels, making the workshop standardized and tidy, improving site utilization, and reducing the labor intensity of manual subcontracting, packaging, and handling.

思源黑体预加载(勿删): JIANGSU LEEV INTELLIGENT EQUIPMENT CO., LTD.